Building small secondary display

Building small secondary display

And some lesson about modularity

Why?

I'm not a big fan of multiple screens, but where it's almost neccessity for me is when Im doing some audio for movie post-production. Main display is used for the audio suite control and on secondary I have video to see what's going on.

What most people do is add secondary display next to the main, but this takes table space that I otherwise need for placing my speakers. And also it's not all that ergonomic, at least for me. So I went with option that I use small display above the main one.

How?

I was lucky and once found in e-waste small SONY monitor. That actually fit quite well what I needed. It was old, low resolution and had VGA connector. I painted it (not so well) black to make it somehow prettier. And one of my dump friends manufactured wall holder for it.

Time for change

But as the time went I started to look for new solution. With better resolution (not really needed but it would be nicer to have it in full HD) and with more modern connection options as it became harder to connect to it with new GPUs. I had hard time to find some already made small monitor. And i stumbled over some article that used dismounted lapton monitor with extra driver as standalone display. So I took dive into eBay and surely, it's not problem to get bare display with driver, for decent price (13.3" IPS N133HSE LCD LED 1080P panel). The only problem was housing, but I have 3D printer at hand, so that should be funny project.

Housing for the display, the lessons

When the display arrived it was sitting on my desk for a while. When I started to do the drawings for the housing couple of issue arrised. First one and expected was that the display housing is too big to be printed at once. So I have to slice it into more pieces and then connect them somehow. Also the display has quite complicated dimensions and lot of features, I kept measuring it but even after couple of testing prints had issues to fit it well. But then I got idea and check display datasheet and found out that actually since these displays are somehow standart for integrating into tablets and laptops it's common to have the dimension published. Somehow that was suprise to me as I was expecting this to be some random noname chinese display.

Next thing was that I had to integrate into the body mounting for the display driver, for buttons and some form of hinges that will be holding the display on wall or something... I was not really sure how all the stuff should look like. I tried couple of times to design back side of that housing to accomodate for these features, but I was never confident enought. I mean If I do some mistake on one feature I have to reprint whole part again...

Then my lazy brain was struck with idea MODULARITY. If I can make it modular I can do each of this independent! And since it's 3D printed it should not be problem to make parts that are somehow more complex.

Main body

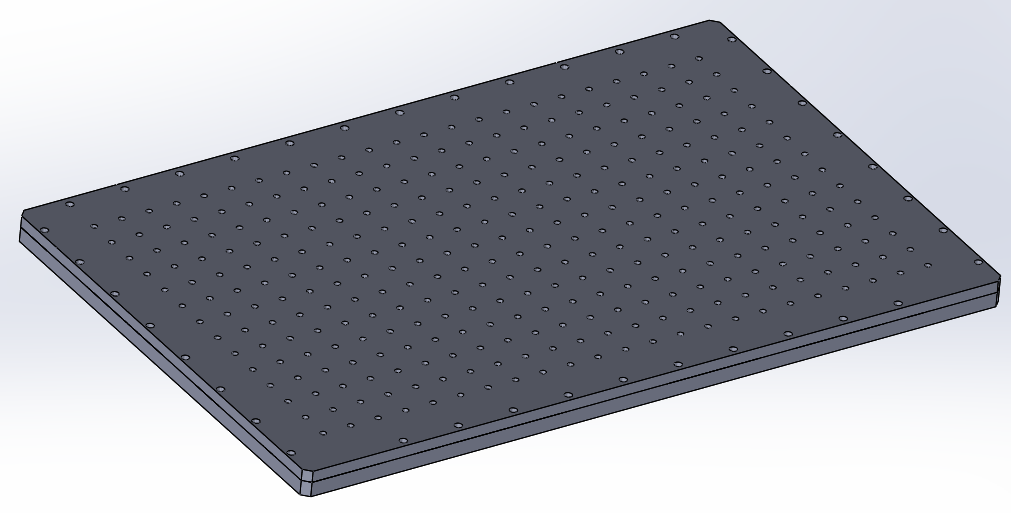

So now thanks to modular design I can start with designing main body on which I will mount all the other stuff. The best way how to do it is to choose screw size and pattern/pitch for holes. So instead of putting holes on specific places you will places holes on specific places only where needed and then creat matrix of holes. In my case I went with M3 screws and 12,5mm pitch. But it's up to application to choose the proper values. Impoertant is do do that decision and stick with it. For desing it means I created lot of holes with 2,5 - 2,7 dimater as this works quite well for M3, it's easy to screw in and holds.

Electronics

Designing holder for electronics is actually quite easy. I started with the PCB holes positions and then added holes for mounting holder on the main body. The same goes for buttons. Absolute position is not neccessary since they can be relatively easily moved around by screwing it where I want.

Display holder

This went thru 3 iterations. First version was three point connection to the wall where I have found out that my brain is not smart enought. Since what I thought would be rigid mount to wall had too many free joints and the display simply did not hold but swang down. So just to have it mounted somehow I created first out of the head solution that I knew would work, but was not really good.

BUT then I finally reallized. I did not reevaluted my requirements and just went with how it was done before. Beacause, What I Want? I want my secondary display above my main... all the time. And if you have one on table and one on wall and you move table, your displayes are not alligned anymore. So the rigth solution is to have secondary display mounted directly on the main display! How simple idea, what an idiot.

This is actually tricky to do since the main display has no mounting points, but one. It ofcourse has vesa mount that is now used for the leg holding the monitor. So I designed extra piece that goes above the leg mounting points and creates extra mounting plane for the secondary monitor mounting. This plane is again just modular platform!

After couple of iterations I have finally produced something Im actually happy about.

Final installation in it's completness. The string on top, holding the screen from tiping over is nice touch to make it less professional and more DIY "like"!

Conclusion

The moral of this story is.

- Going modular is useful, but it's less cost effective. I had to use lot of screws, it's heavier etc. It's not the best tuned solution for the problem. But when you are developing and you are not sure about requirements and how the features shoudl look like its great tool to explode problem into smaller ones. The right approach would be to now when I know how all the stuff should look like do new revision without modularity. But its my DIY project for fun, and I'm lazy :)

- I think this hold even for SW and other projects.

- Everytime you design something, stop for while and think about what is the goal/requirement, what you want to achive. Not how, but what, and value tools that are used only based on that how it helps you achive the goals.

- Making this was not neccessary, I could have just buy something like this already done. But thanks to this project I learned couple of usefull things, that helps me in my job. Value the work you do based on what you learn, only if you are not learning value the work by raw outcome.

Komentáře

Okomentovat